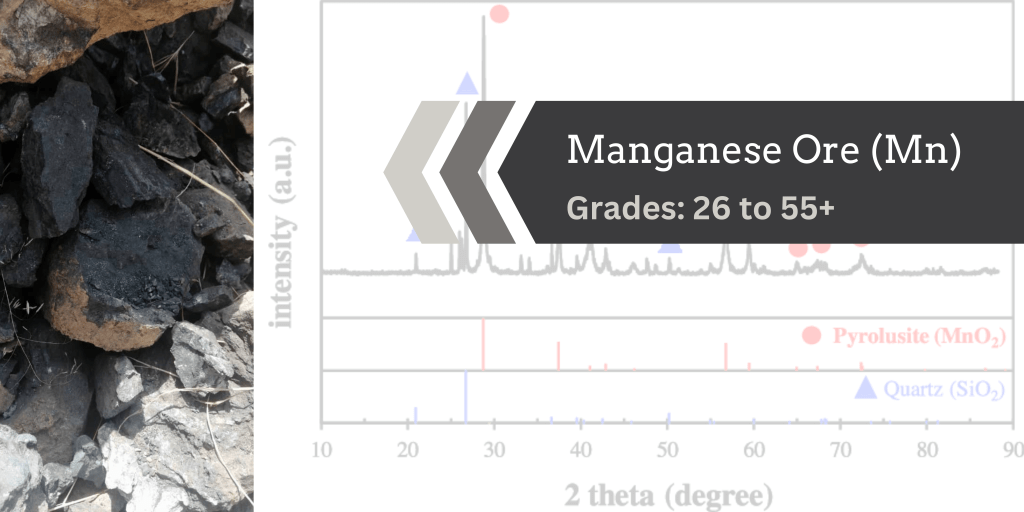

Manganese (Mn) ore is categorized based on its manganese content, impurities, and intended industrial applications. Below are the major grades and their uses:

1. High-Grade Manganese Ore (Mn > 44%)

- Uses:

- Primarily used in ferromanganese and silicomanganese production (steelmaking).

- Used in battery manufacturing (electrolytic manganese dioxide – EMD).

- Important for chemical applications like potassium permanganate production.

2. Medium-Grade Manganese Ore (Mn 30–44%)

- Uses:

- Steelmaking (ferromanganese & silicomanganese).

- Alloy production (for cast iron and superalloys).

- Some chemical and battery industries.

3. Low-Grade Manganese Ore (Mn < 30%)

- Uses:

- Often beneficiated (processed) to upgrade Mn content.

- Used in cement, glass, and ceramics industries.

- Some low-grade ores are used in fertilizers and animal feed additives.

Industry Applications of Manganese Ore

- Steel Industry (90% of global Mn consumption)

- Manganese improves steel strength, toughness, and resistance to wear.

- Used in ferroalloys like ferromanganese (FeMn) and silicomanganese (SiMn).

- Battery Industry

- Electrolytic manganese dioxide (EMD) is used in lithium-ion and alkaline batteries.

- Manganese sulfate is crucial for EV battery cathodes.

- Chemical Industry

- Used in potassium permanganate for water treatment and pharmaceuticals.

- Foundry and Alloy Industries

- Enhances the durability and hardness of aluminum, copper, and nickel alloys.

- Other Uses

- Used in pigments, fertilizers, and ceramics.

- Some applications in medical and environmental remediation.

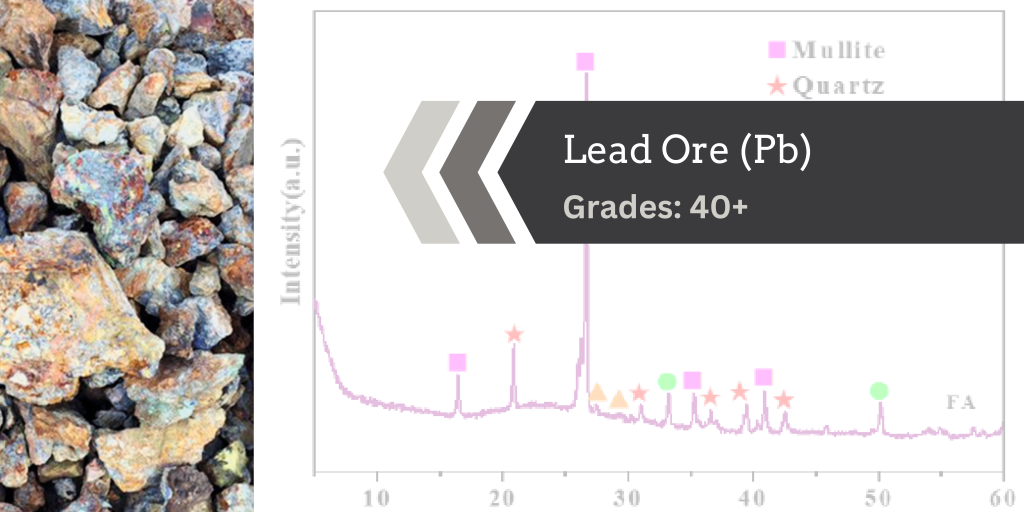

Lead ore is mainly found in the form of galena (PbS), which is the most important lead mineral, often associated with silver, zinc, and copper. The grade of lead ore is categorized based on lead (Pb) content and impurities.

Lead Ore Grades

1. High-Grade Lead Ore (Pb > 50%)

- Characteristics:

- Typically in the form of galena (PbS) with high purity.

- Contains minimal impurities.

- Uses:

- Directly processed for lead metal production in smelting and refining.

- Used in high-purity applications, including batteries and radiation shielding.

2. Medium-Grade Lead Ore (Pb 20–50%)

- Characteristics:

- Often found mixed with other metals like zinc and silver.

- Requires concentration through beneficiation processes (flotation, gravity separation).

- Uses:

- Used for lead refining after concentration.

- Major source for lead-acid battery production and industrial lead.

3. Low-Grade Lead Ore (Pb < 20%)

- Characteristics:

- Contains a significant amount of impurities.

- Requires intensive processing for lead extraction.

- Uses:

- Often processed using froth flotation to increase Pb content.

- Used in secondary lead production or mixed-metal recovery.

Industry Uses of Lead

1. Battery Industry (80% of lead consumption)

- Lead-acid batteries for automotive, industrial, and backup power applications.

- Used in electric vehicles (EVs), solar power storage, and uninterruptible power supplies (UPS).

2. Construction and Infrastructure

- Lead sheets and pipes for roofing, waterproofing, and old plumbing systems.

- Used in cable sheathing for telecommunications and power cables.

3. Radiation Shielding & Medical Applications

- Used in X-ray and gamma-ray shielding (hospitals, nuclear facilities).

- Found in protective clothing and lead glass.

4. Alloying & Industrial Uses

- Alloyed with tin to create solders used in electronics.

- Used in bearing metals, lead-bronze alloys, and leaded glass.

5. Chemical Industry

- Used in lead-based pigments, lead oxides, and stabilizers for plastics and coatings.

- Historically used in paints and gasoline additives, though now restricted due to toxicity concerns.

3. Environmental & Recycling Considerations

- Lead is highly toxic, and strict environmental regulations control its mining and usage.

- Recycling of lead-acid batteries is a major source of secondary lead.

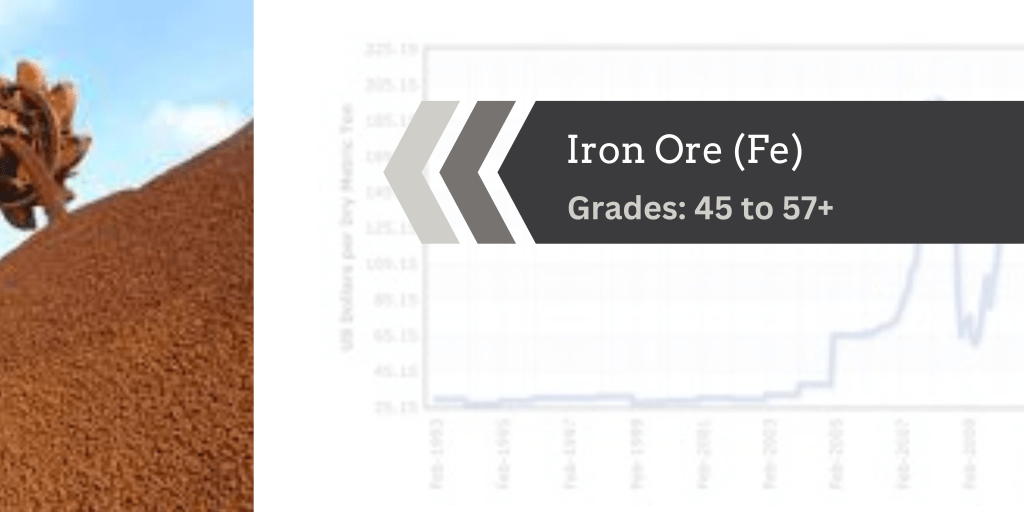

Iron ore is classified based on its iron (Fe) content and impurities such as silica (SiO₂), alumina (Al₂O₃), phosphorus (P), and sulfur (S). The quality of iron ore affects its suitability for various industrial applications, primarily in the steel industry.

Iron Ore Grades

1. High-Grade Iron Ore (Fe > 62%)

- Examples:

- Hematite (Fe₂O₃) – Commonly found in Australia, Brazil, and India.

- Magnetite (Fe₃O₄) – Found in Sweden, Canada, and Russia.

- Characteristics:

- Low impurities, requiring minimal beneficiation.

- Preferred for high-quality steel production.

- Uses:

- Directly used in blast furnaces and direct reduction iron (DRI) processes.

- Essential for premium-grade steel manufacturing.

2. Medium-Grade Iron Ore (Fe 55–62%)

- Examples:

- Lower-grade hematite and magnetite ores.

- Goethite (FeO(OH)) – Common in tropical regions.

- Characteristics:

- Requires beneficiation to remove impurities.

- Used in sintering and pelletizing before being fed into blast furnaces.

- Uses:

- Used in standard steel production after upgrading.

3. Low-Grade Iron Ore (Fe < 55%)

- Examples:

- Limonite (FeO(OH)·nH₂O) – High moisture content.

- Taconite – A sedimentary iron formation with significant impurities.

- Characteristics:

- High levels of silica, phosphorus, and other impurities.

- Requires intensive beneficiation (crushing, grinding, magnetic separation).

- Uses:

- Typically processed into iron ore pellets or used in sintering plants.

- May be blended with high-grade ores to improve Fe content.

Industry Uses of Iron Ore

1. Steel Industry (98% of iron ore consumption)

- Iron ore is the primary raw material for steelmaking.

- Used in blast furnaces to produce pig iron, which is then converted into steel.

- Used in electric arc furnaces (EAFs) for producing recycled steel.

2. Automotive & Machinery Manufacturing

- High-strength steel is used in cars, ships, trains, and heavy machinery.

3. Construction Industry

- Steel derived from iron ore is widely used in buildings, bridges, pipelines, and skyscrapers.

4. Infrastructure Development

- Used in railways, tunnels, power plants, and water supply networks.

5. Iron-Based Chemicals

- Iron oxides are used in pigments, coatings, and industrial catalysts.

- Used in fertilizers and water purification processes.

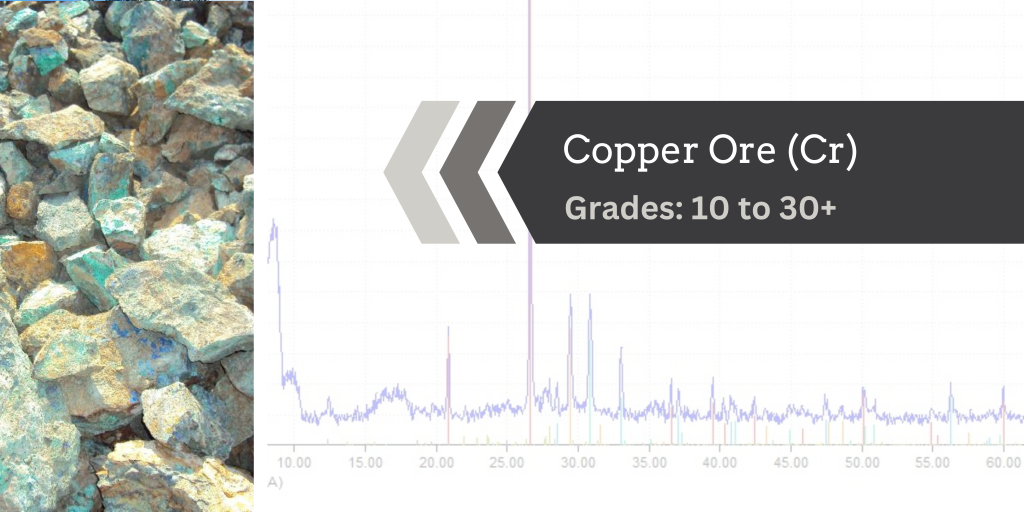

Copper ore is classified based on its copper (Cu) content and associated minerals. It is widely used in various industries, mainly in electrical, construction, and manufacturing sectors.

Copper Ore Grades

1. High-Grade Copper Ore (Cu > 2%)

- Examples:

- Chalcocite (Cu₂S) – High copper content, found in supergene-enriched deposits.

- Bornite (Cu₅FeS₄) – High-grade but less common than chalcocite.

- Characteristics:

- Requires minimal processing before smelting.

- High recovery rates and cost-effective extraction.

- Uses:

- Directly processed into copper concentrates for refining.

- Preferred for high-purity applications (electronics, electrical wiring).

2. Medium-Grade Copper Ore (Cu 0.5–2%)

- Examples:

- Chalcopyrite (CuFeS₂) – The most abundant copper mineral.

- Malachite (Cu₂CO₃(OH)₂) and Azurite (Cu₃(CO₃)₂(OH)₂) – Oxide ores.

- Characteristics:

- Requires flotation processing to increase copper concentration.

- Common in porphyry copper deposits (Chile, Peru, USA).

- Uses:

- Major source for copper refining and smelting.

- Used in construction, manufacturing, and infrastructure projects.

3. Low-Grade Copper Ore (Cu < 0.5%)

- Examples:

- Porphyry deposits – Large, low-grade deposits found in open-pit mines.

- Copper-bearing shale – Found in Poland and Germany.

- Characteristics:

- Requires heap leaching or bioleaching for extraction.

- Lower recovery rates and higher processing costs.

- Uses:

- After beneficiation, used for copper refining.

- Often blended with higher-grade ores for cost-effective smelting.

Industry Uses of Copper

1. Electrical and Electronics (60% of copper consumption)

- Copper wiring, conductors, and electrical components.

- Used in power transmission, transformers, and motors.

- Essential for renewable energy (solar, wind, EV batteries, charging stations).

2. Construction and Infrastructure

- Used in plumbing, roofing, and industrial machinery.

- Key material for pipes, heating systems, and architectural structures.

3. Transportation Industry

- Essential for electric vehicles (EVs), aircraft, railways, and ships.

- Used in brakes, radiators, and connectors.

4. Manufacturing and Industrial Applications

- Alloyed to produce brass (Cu + Zn) and bronze (Cu + Sn).

- Used in heat exchangers, mechanical components, and heavy equipment.

5. Chemical and Medical Applications

- Copper sulfate used in fungicides, agriculture, and water treatment.

- Antimicrobial properties make copper useful in medical devices and hospital surfaces.

Chrome ore, primarily in the form of chromite (FeCr₂O₄), is a key source of chromium, essential for stainless steel production, refractory materials, and chemicals. The ore is classified based on its Cr₂O₃ content and impurities such as silica (SiO₂), iron (Fe), and alumina (Al₂O₃).

Chrome Ore Grades

1. High-Grade Chrome Ore (Cr₂O₃ > 48%)

- Characteristics:

- Low impurities (SiO₂ < 5%, FeO < 12%).

- High Cr/Fe ratio (≥3:1), which is ideal for ferrochrome production.

- Uses:

- Primarily used in ferrochrome (FeCr) production for stainless steel.

- Some high-grade ores are used in chemical and refractory applications.

2. Medium-Grade Chrome Ore (Cr₂O₃ 40–48%)

- Characteristics:

- Moderate Cr/Fe ratio (2.5:1 to 3:1).

- Requires beneficiation to increase Cr₂O₃ content.

- Uses:

- Used in ferrochrome smelting after concentration.

- Suitable for foundry applications and chrome-based chemicals.

3. Low-Grade Chrome Ore (Cr₂O₃ < 40%)

- Characteristics:

- Higher levels of iron, silica, and alumina.

- Requires processing (gravity separation, flotation, or magnetic separation).

- Uses:

- Used in refractory materials and chromite sand for foundries.

- Some applications in chromium chemicals after beneficiation.

Industry Uses of Chrome Ore

1. Stainless Steel Production (85% of global chromium consumption)

- Ferrochrome (FeCr), produced from chrome ore, is a critical alloying element in stainless steel.

- Enhances corrosion resistance, hardness, and strength.

2. Refractory and Foundry Applications

- Chrome ore is used in heat-resistant refractory bricks for furnaces, kilns, and ladles.

- Chromite sand is used in casting molds for metal foundries due to its heat resistance.

3. Chemical Industry

- Used in sodium dichromate, chromium sulfate, and chromic acid production.

- Essential for leather tanning, pigments, and metal plating.

4. Aerospace and Automotive Industries

- Chromium-based alloys are used in jet engines, automotive parts, and industrial machinery.

- Increases wear resistance and durability.

5. Ferroalloy and Superalloy Production

- Chrome ore is used in ferrochrome alloys for specialized applications in tools and high-temperature environments.